Spray foam insulation is a foundational element in thermal control, air sealing, and vapor management. Builders face important performance and code compliance decisions based on the material’s structural behavior and environmental fit. This guide presents the technical facts behind open vs closed cell spray foam insulation, allowing contractors to specify insulation based on performance, not promotion.

Foam Formation and Structural Behavior

Spray foam insulation begins as a two-part liquid that expands into a hardened matrix once applied. While both systems rely on this chemical reaction, the cell structure that results sets each type apart in function and field performance.

Expansion and Cellular Construction

Open cell spray foam forms with ruptured gas pockets that leave behind a soft, permeable structure. It expands rapidly—often reaching depths of 3 inches in a single pass—while closed cell foam expands more slowly, typically reaching just 1 inch per pass.

This broken-cell matrix makes the material breathable but also reduces density and strength. Closed cell foam cures into a rigid, sealed network that blocks air and vapor while adding dimensional support to the cavity.

Weight, Density, and Surface Strength

Open cell formulations typically weigh around 0.5 pounds per cubic foot and offer light expansion with minimal surface tension. Closed cell options range from 1.7 to 2.0 pounds per cubic foot and deliver a dense, high-bond surface that resists movement and provides structure.

Thermal Resistance and R-Value Efficiency

Foam type directly affects how much insulation is delivered per inch—and how much space is required to meet energy code targets. Installers must evaluate both material properties and cavity conditions.

R-Value Per Inch

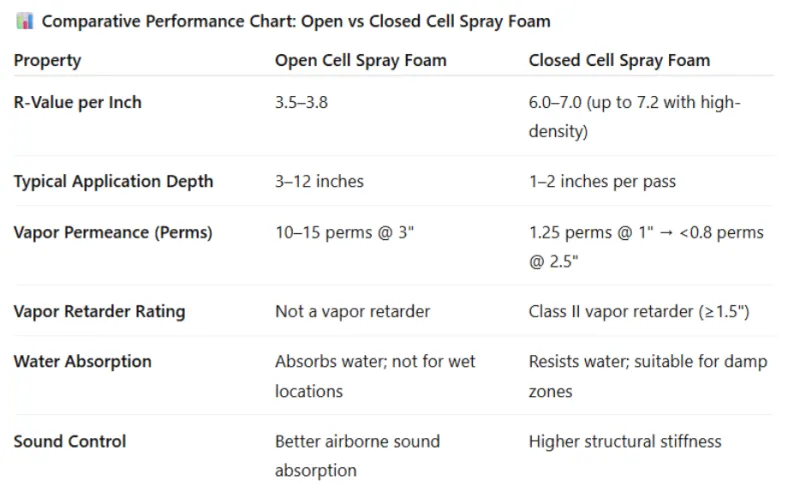

Open cell foam provides approximately 3.5 to 3.8 R per inch, requiring greater thickness to match code in colder regions. Closed cell foam reaches between 6.0 and 7.0 R per inch, with some high-density formulations exceeding R-7.2. This enables thinner insulation layers in shallow wall or roof assemblies. This difference often drives the initial comparison of open vs closed cell spray foam insulation during the design process.

While R-value measures resistance to heat flow, some assemblies may also consider U-value for total thermal transmittance—especially in energy modeling.

Material Fit for Cavity Constraints

Closed cell foam works well in conditions with limited space or structural needs. Open cell foam may over-expand in narrow voids and require trimming or design modification to avoid conflict with mechanicals or trim systems.

Moisture Resistance and Vapor Control

Water exposure and vapor drive affect long-term insulation performance. Spray foam must be selected based on both immediate exposure and seasonal vapor movement.

Vapor Permeance Ratings

Open cell foam allows vapor to pass freely and requires a dedicated vapor barrier in exterior walls, roofs, or basements. Closed cell foam achieves a Class II vapor retarder rating at 1.5 to 2 inches, with perm values ranging from 1.25 at 1 inch to below 0.8 at 2.5 inches. This often eliminates the need for additional membrane layers in most assemblies.

Water Intrusion and Absorption Risk

Closed cell foam blocks liquid water and resists mold growth in high-moisture areas. Open cell foam absorbs water and loses performance in wet conditions, making it inappropriate for basements, crawl spaces, or slab-contact locations.

Acoustic Control and Structural Value

Some projects call for insulation that provides more than thermal resistance. Spray foam also contributes to interior sound performance and wall strength.

Sound Absorption Differences

Open cell foam dampens airborne sound due to its soft structure and porous surface. Closed cell foam reflects more sound but contributes structural stiffness to walls, ceilings, and sheathing transitions.

Wall Reinforcement Benefits

Closed cell foam adds compressive strength to wall assemblies, reducing flex and vibration under load. In engineered assemblies, this may reduce the need for additional blocking or bracing.

Application Fit by Climate and Zone

Spray foam must align with environmental stressors, exposure risks, and building envelope location. Proper product selection reduces callbacks and prevents premature failure.

Climate-Specific Selection

Closed cell spray foam is often required in colder zones, high-humidity regions, and assemblies with vapor barrier code triggers. Material recommendations may shift along climate boundaries—such as north versus south of Pennsylvania—based on dew point conditions and long-term moisture load expectations. Open cell spray foam performs well in interior walls and ceilings where humidity remains low and assemblies remain protected.

Location and Substrate Planning

Open cell foam requires environmental control during application and should only be used on clean, dry, conditioned substrates. Closed cell foam tolerates more variation but still demands proper lift thickness and substrate temperature control.

Environmental Impact and Compliance Factors

Contractors balancing energy efficiency with sustainability must weigh chemical content, blowing agent, and emissions status. Certification and compliance often influence bid specs and approval timelines.

Blowing Agent Composition

Closed cell foam now uses HFO (hydrofluoroolefin) technology with reduced global warming potential. Open cell foam often uses water or CO₂-based expansion systems and already meets most state environmental benchmarks.

Emissions Ratings and Code Approvals

Both foam types must meet emissions requirements for residential and commercial use. Choosing certified products from recognized programs such as GREENGUARD helps streamline permitting and compliance.

Many closed and open cell formulations also meet low-VOC standards under GREENGUARD Gold or LEED criteria, helping projects comply with emissions caps for schools, healthcare, or other sensitive environments.

Product Performance and Brand Options

Once building needs are defined, the choice of spray foam must align with structural, thermal, and environmental conditions. Fastener Systems manufactures both open and closed cell products for specific field conditions.

Closed Cell Foam Applications

Closed cell foam from Fastener Systems is engineered for basement walls, crawl spaces, rim joists, and exterior sheathing. It resists vapor drive, prevents water absorption, and reinforces wall cavities under structural load. These characteristics make it a clear choice for contractors comparing open vs closed cell spray foam insulation on jobs where moisture resistance is critical.

Open Cell Foam Applications

Open cell spray foam is ideal for interior partitions, conditioned ceilings, and noise-dampening interior assemblies. It provides cost-effective air sealing while maintaining consistent expansion and adhesion.

Installation Standards and Jobsite Variables

Regardless of foam type, installation practices affect final performance. Applicators must follow strict protocols for lift thickness, cure time, ventilation, and environmental conditioning. Spray behavior, expansion rate, and cure sensitivity differ significantly between open vs closed cell spray foam insulation, which makes proper training and sequencing essential on multi-foam job sites.

Installation Process Requirements

Closed cell foam must be installed in thin passes to avoid thermal shrinkage and internal delamination. Manufacturers recommend a maximum of 2 inches per lift. Open cell foam, under controlled site conditions, may be installed in thicker lifts—sometimes up to 12 inches—without compromising cure integrity. Open cell foam expands more aggressively and requires tighter control over jobsite humidity and substrate exposure.

Field Consistency and Quality Control

Failure to follow specifications leads to adhesion failure, uneven expansion, or long-term degradation. Field crews must receive training on each foam type’s behavior and site requirements to prevent callbacks or code failures.

Vapor Retarder Threshold and Code Compliance

Building code mandates vary by state and application, but vapor barrier performance is frequently misunderstood. Foam thickness determines compliance—not just product label.

Closed Cell Thresholds

Closed cell foam reaches Class II vapor retarder status at 1.5 to 2 inches. This simplifies assemblies and eliminates the need for exterior vapor barriers in many cases.

Open Cell Limitations

Open cell foam cannot function as a vapor retarder and will require membrane reinforcement in any climate zone where vapor movement must be restricted by code.

Evaluating Foam Type by Building Requirements

Choosing between open vs closed cell spray foam insulation depends on the project’s specific moisture exposure, thermal targets, cavity dimensions, and acoustic needs. Open cell performs best in interior assemblies shielded from humidity and bulk water. Closed cell provides higher thermal value, structural reinforcement, and vapor control where conditions demand more from the material.

Build with Fastener Systems Spray Foam Products for Code-Level Durability

We manufacture high-performance spray foam systems for both structural and interior insulation needs. Our product line includes both open and closed cell formulations designed for jobsite consistency and compliance in real-world conditions. Contact us today for more information.