In modern building science, closed cell spray foam insulation is a major contributor to energy efficiency and moisture control. It delivers high thermal insulation, structural rigidity, and moisture resistance across a wide range of assemblies. It’s used across wall, roof, and foundation assemblies where insulation must also deliver moisture resistance and structural rigidity.

What Closed Cell Spray Foam Is and How It Works

Closed cell foam starts as a liquid blend that expands rapidly when sprayed, forming a dense structure that locks in insulation value and bonds directly to the surface.

Material Composition and Expansion Behavior

Closed cell spray foam is made from two components that mix and expand at the point of application. The closed-cell structure traps blowing agents, forming a dense, rigid mass that adheres to substrates like metal, masonry, or concrete. This structure enables high insulating values, moisture resistance, and mechanical durability once cured.

Key Properties by Thickness

When applied in moderate thicknesses, the foam can serve as both an air barrier and a vapor retarder, depending on the assembly design and climate zone. These dual-control properties support tighter envelopes and reduced material layering.

Physical and Environmental Performance Advantages

Once installed, closed cell foam responds to environmental forces by reinforcing wall cavities, blocking moisture, and limiting unwanted heat transfer.

Thermal Resistance and HVAC Efficiency

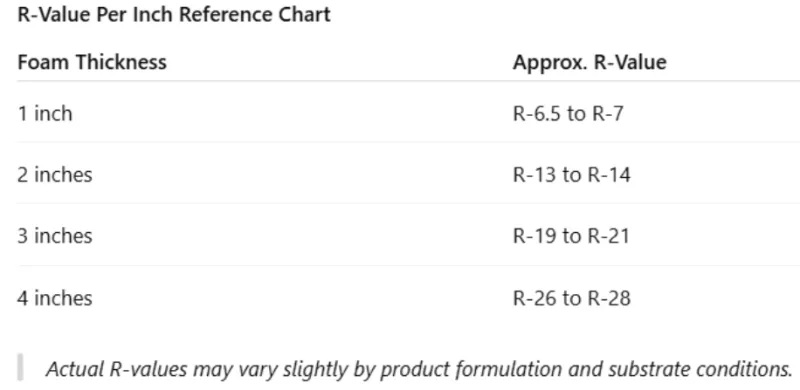

With R-values up to R-7 per inch, closed cell spray foam insulation minimizes heat transfer. It reduces thermal bridging and enables tighter envelopes, which can lead to measurable reductions in heating and cooling demand. Buildings insulated with spray foam often show improved efficiency when envelope design is optimized for performance.

Air Barrier and Indoor Air Quality

Closed cell spray foam forms a rigid seal that limits uncontrolled air movement through wall and roof assemblies. By minimizing infiltration, the foam helps stabilize interior temperature and supports better air quality and occupant comfort.

Structural Reinforcement Under Load

Once cured, the foam forms a hardened layer that resists flexing, shifting, or sagging. It adds shear resistance to wall cavities, particularly in high-wind zones or open-span framing. This reinforcement does not replace framing, but it reduces movement that can lead to cracking or loss of airtightness.

Moisture and Vapor Control Benefits

Closed cell spray foam limits vapor transfer and prevents condensation inside wall cavities. This protection is especially valuable in basements, crawl spaces, rim joists, or metal buildings. In many assemblies, closed cell spray foam insulation eliminates the need for separate moisture barriers.

Water Tolerance in Challenging Environments

In some applications, closed cell foam may tolerate short-term water exposure better than conventional insulation, especially in areas where drying conditions are well managed.

Limitations and Specification Considerations

Some conditions require additional planning during use or installation.

Cost, Coverage, and ROI Outlook

Closed cell spray foam costs more per square foot than fiberglass, cellulose, or open cell. Some projects pair closed cell foam with other insulation types to reduce material costs while still meeting thermal and moisture control targets. Long-term energy savings, extended lifespan, and reduced callbacks often justify the up-front cost.

Acoustics, Ventilation, and Cure Management

Due to its rigidity, closed cell foam transmits sound more readily than softer materials. It must be applied with proper ventilation and personal protective equipment (PPE) to ensure safe handling during mixing and spray. Improper curing can result in off-gassing, poor adhesion, or lingering odor, especially in tight cavities or low-temperature conditions.

Environmental and Regulatory Factors

Manufacturers continue to refine spray foam formulations to meet evolving environmental standards related to blowing agents. Local building codes may also require thermal or ignition barriers in exposed assemblies.

Application-Specific Use Cases

Closed cell spray foam insulation performs best in locations where air control, structural reinforcement, and moisture resistance must be delivered in compact or demanding assemblies.

Exterior Walls and Roofing Systems

The foam performs well in wood-frame and metal-framed exterior walls, especially in climate zones with large temperature swings. It can also be used in unvented roofing systems or cathedral ceilings that require both insulation and air control.

Basements, Crawl Spaces, and Below-Grade Installs

The vapor-retarding properties of closed cell spray foam insulation make it ideal for subgrade applications where humidity and groundwater are present. It eliminates the need for separate moisture barriers in many assemblies.

Industrial, Agricultural, and Metal Structures

In metal building retrofits and agricultural facilities, closed cell spray foam insulation provides both thermal protection and structural reinforcement in a single applied system. It resists air leaks around fasteners and framing joints common in pole buildings and pre-engineered systems.

Installation Process and Quality Control

Effective application of closed cell spray foam insulation depends on surface prep, lift strategy, and curing conditions—all of which affect bond strength and insulation value.

Surface Prep and Lift Guidelines

Surfaces must be clean, dry, and free of dust or oil. The foam is applied in layers, or “lifts,” with cure time between applications. Excessive lift thickness or cold surfaces can compromise bond strength and lead to voids or delamination.

Field Inspection and Performance Testing

Post-install, contractors measure foam depth to verify insulation value. Higher R-values can be reached with thicker applications, depending on the spray foam system and cavity depth. Infrared imaging and blower door tests can confirm the effectiveness of the installed barrier.

Choose the Right Spray Foam System for Your Project

At Fastener Systems, we offer spray foam products designed for performance, reliability, and compatibility with modern building envelopes. Our closed cell formulations are engineered for long-term stability in demanding structural assemblies. Contact us today for more information.