Jobsite delays and structural failures often trace back to overlooked fasteners. In metal construction, performance hinges on torque, alignment, and hold strength. Choosing the right hex head self drilling screw ensures metal-to-metal connections remain secure under jobsite stress.

What Is a Hex Head Self Drilling Screw?

This screw combines a Tek drill point, precision threads, and a six-sided drive head into one unitized fastener. These components work together to cut, tap, and seat in a single pass—eliminating the need for pre-drilling or tool changes.

How Drill Points and Threads Work Together

The drill point creates a borehole through the substrate, while the threads cut and hold. This paired function allows contractors to drive through steel up to 0.5 inches thick, depending on the drill-point number. A #2 point works for 16- to 22-gauge steel; a #5 can cut heavier structural members. Fastener Systems offers Tek 1, Tek 3 and Tek 5 fasteners rated for various applications. All are made from SAE 1022 carbon steel and coated with a 1000 hour salt spray coating.

The Role of the Hex Head in Installation

The six-sided head allows for positive nutsetter engagement and transfers torque directly from the driver to the fastener. This allows for clean, controlled installation, even at panel edges or overhead. Magnetic drivers improve stability during fastening, especially when the fastener must be set at an angle.

Why Tip and Material Selection Affect Performance

Not all self drilling screws perform the same in every application. Selecting the right material, drill point, and washer type directly affects longevity, seating pressure, and sealing performance.

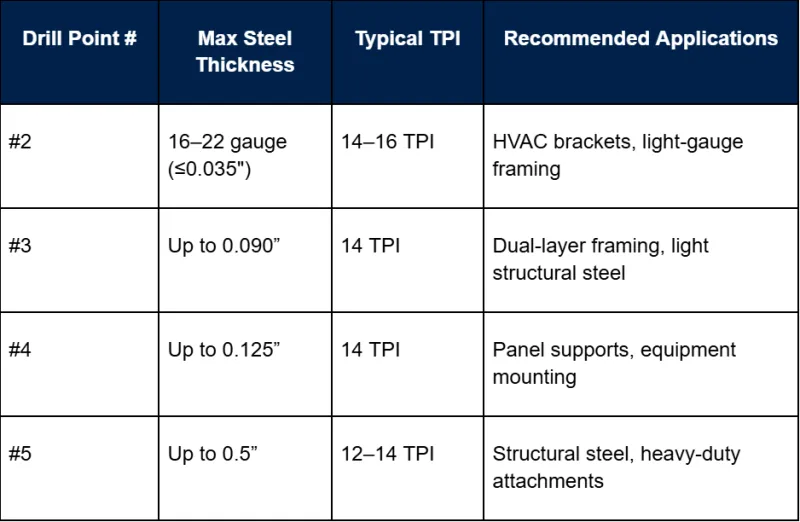

Drill Point Numbers Match Steel Thickness

Each drill-point number corresponds to a steel gauge range. Using the wrong tip can cause screw stall-out, thread shearing, or incomplete fastening. Contractors should always verify point type against the metal being joined. As detailed in the Fastener Systems blog, Tek 3 screws are optimal for thinner steel, while Tek 5 screws support heavier gauge assemblies without pilot holes.

Hex Head Self Drilling Screw Spec Reference Table

Material and Coating Matter in Harsh Conditions

A hex head self drilling screw made of stainless steel resists rust in marine and coastal builds. Fastener Systems offers long self-drilling screws in 410 stainless for high-corrosion environments. Zinc-plated carbon steel models with clear CR6+ chromate or yellow dichromate finishes are also available, offering 1,000-hour salt-spray resistance with optional Ruspert coating for added durability. FSI also offers a bi-metal fastener that has a carbon steel drill point and starter threads with a 300 series stainless steel screw shank and head. This combines the drilling capacity of hardened carbon steel with the corrosion properties of stainless.

Washer Design Affects Seal Integrity

Washer-backed fasteners are used where weather intrusion is a concern. A bonded EPDM washer creates a compression seal between the fastener head and substrate. The washer also absorbs vibration and keeps the screw seated under movement. FSI also offers a FastSeal Hex Flange head screws that features an EPDM washer that becomes concealed under the flange head during installation offering a more aesthetically pleasing finish and prevents the washer from being exposed to environmental factors.

Installation Control Prevents Field Failures

Installation method and tool compatibility directly influence how well a fastener holds. Operators must select drivers that match the tip and thread geometry for proper performance.

Power Tools and Torque Control

Using too much speed can burn coatings or deform the cutting tip. Underpowered tools may leave the screw partially seated or misaligned. According to Fastener Systems’ installation guidance, self-drilling fasteners perform best when installed at up to 1,500 RPM. That speed allows clean cutting through 0.125″ steel without overheating or damaging the flute. Impact drivers are not recommended as they tend to damage the drill points during installation resulting in a less than ideal hole being formed.

Borehole Integrity Supports Long-Term Stability

The cutting action must leave clean edges around the hole to avoid leaks, rust, or panel shifting. A clean bore maintains pressure and reduces the risk of loosening during temperature swings or vibration cycles.

Application Examples Across Metal Trades

A hex head self drilling screw is used in roofing, framing, mechanical support, and HVAC ductwork—each requiring distinct design choices based on load, exposure, and alignment needs.

Metal Panel Systems and Cladding

Fasteners in roof decks or wall cladding must resist wind uplift and prevent water intrusion. Stainless screws with bonded washers are often required by specifiers to maintain envelope performance. Fastener Systems' guide outlines head styles and coatings for metal roofing systems based on substrate and weather conditions.

Light-Gauge Steel Framing

Structural connections in 18- to 22-gauge framing call for fasteners with high pullout resistance and precision alignment. A fastener with a #2 or 3 drill point can set reliably through dual-layer connections without walk-off.

HVAC, Electrical, and Mechanical Installs

Fastening ducts, conduit brackets, or MEP supports demand fasteners that can seat quickly in tight or overhead spaces. The hex head offers stable engagement, and shorter lengths reduce spinout risk in thinner metals.

Choosing the Right Screw for Project Requirements

Fastener choice should reflect real jobsite needs—not just price or size. Each variable—tip number, coating, washer, and head—must match the assembly environment.

Matching Screw Geometry to System Loads

Thicker panels, dynamic movement, or uplift demands require longer screws with stronger threads and higher seating torque. Choosing the wrong screw can lead to system failure or repeated maintenance.

Corrosion Behavior Defines Life Expectancy

Outdoor and industrial installations expose screws to heat, condensation, or chemical vapor. Using stainless or epoxy-coated options extends service life and minimizes callbacks.

Lifecycle Costs Outweigh Initial Price

Initial cost differences may seem minor, but rework, failure, and water intrusion multiply total ownership costs. A hex head self drilling screw that fails in one season creates more expense than a longer-lasting alternative.

Install with Confidence Using Fastener Systems Products

Fastener Systems offers a range of hex head and Fastseal self drilling screw solutions available in 1000’s of colors, engineered specifically for metal applications. These fasteners are built for clean seating, corrosion resistance, and reliable drill-point engagement across standard gauges. With bonded washer options, stainless steel variants, and controlled tip geometry, we help you complete your job right the first time. Contact us today for more information.