Although self-tapping and self-drilling screws may appear similar, they are actually quite different. Self-tapping screws are designed for use with softer metals, while self-drilling screws can be used on a wider range of materials. Additionally, customers frequently ask for one type of screw when they actually need the other. To help clear up any confusion, we have outlined the similarities and differences between these two types of screws, as well as guidance on when to use each one.

Self-Drilling Screws

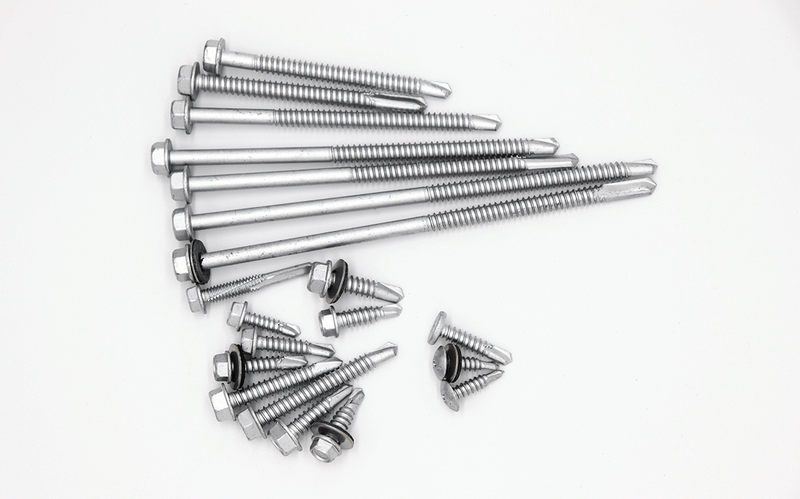

It's easy to differentiate self-drilling screws from regular screws by looking at the tip. Self-drilling screw points curve gently and are shaped like a twist drill, while regular screw points are more blunt. In addition, self-drilling screws come in different lengths, but all have standardized drill points that are identifiable by number (1 through 5). This number determines the length and thickness of the point. Lastly, self-drilling screws vary in head and drive style, with Phillips, Hex or Square being the most common types.

Self-drilling screws are specially designed to fasten metal to metal quickly and easily. Utilizing their capacity to handle drill speeds up to 1,500 RPM allows them to drive through thicknesses up to 0.125 inches, which makes them useful for many types of projects.

Self-drilling screws are different than self-tapping screws, because they don't require a pilot hole to be cut before being used. This saves you the extra step of having to drill first, then fasten.

Purposes for Self-Drilling Screws

If you're working with concrete, block, or brick and need a screw that can penetrate all those materials easily, self-drilling screws are the way to go. Please note that depending on how thick the material is, you might need to create a pilot hole beforehand.

- Countersunk self-drilling screws will leave the head up to 3/16" of an inch below the finished surface, so the screw heads can be hidden.

- Low-Profile Head Self-Drilling Screws attach framing securely to any metal surface.

Best Applications

Self-drilling screws are simple to use for various purposes, including:

- HVAC projects

- Cladding

- Metal roofing

- Steel framing

Construction tasks that use light gauge metal assemblies or metal buildings can also benefit from self-drilling screws. Self-drilling screws can be used on many surfaces, like metal to metal, or wood to metal fixtures. They also work well with light materials, so you're not limited to only using them for heavy duty projects. In general, these types of specialized screws have more applications than self-tapping screws.

Self-Tapping Screws

There are three types of self-tapping screws:

- Thread-forming

- Thread-cutting

- Thread-rolling

Self-tapping screws come in different shapes and sizes, with pointed, blunt or flat tips.

- Thread-forming screws tap and create threads in a pre-drilled hole.

- Thread-rolling screws roll or extrude threads with zero clearance between screw and material.

- Thread-cutting screws create new threads that replace the original in metals.

Thread-cutting screws are commonly used as fasteners, particularly for products or materials that require periodic maintenance. In comparison to thread-forming screws, which also gather material as they're turned, but with more force, thread-cutting screws typically result in less wear and tear on the target material - which makes them ideal for joining wood and plastics together.

Self-tapping screws require a pre-existing pilot hole to function, while self-drilling screws do not. The size of the drill or punch hole is also crucial - too big and the screw will become loose, too small and the material can break.

Best Applications

There are many uses for self-tapping screws, including attaching metal brackets to wood and inserting screws into plastic. They work with many different materials:

- Metals

- Plastics

- Iron

- Aluminum

- Brass

- Bronze

Problems When Choosing the Wrong Screw for the Task

To avoid any problems, you first need to make a pilot hole before using self-drilling screws. This can be done with either a drill or a punch. If the hole is too large, the screw will become loose and won't work as it should. However, if it's too small, there is a chance of snapping the screw or putting undue strain on materials

Although self-drilling screws are also self-tapping, not all self-tappers can drill their own threads. If you try to use a self-tapper on wood or metal without first making a pilot hole, chances are it won't work as intended--or at all. Self-drillers eliminate the need for a separate pilot hole, because they can tap into wood or metal by themselves. Since these two types of screws serve different purposes, it's important not to confuse them or use them interchangeably.

Get the Right Screws for Every Task with Fastener Systems - Shop Our Catalog

At Fastener Systems, we understand the importance of finding the right self-tapping and self-drilling screws for your project. Our professional staff can help you make the right choice. We also have a wide selection of other tools, such as spray foams, tapes, and safety equipment.

At FSI, we go above and beyond to ensure that you get the best products available on the market, with no compromises in quality. For more information about our products or if you'd like to inquire about bulk orders, contact us today!

We also offer a full-line catalog. Let us show you why so many customers have trusted us with their projects since 1984!